|

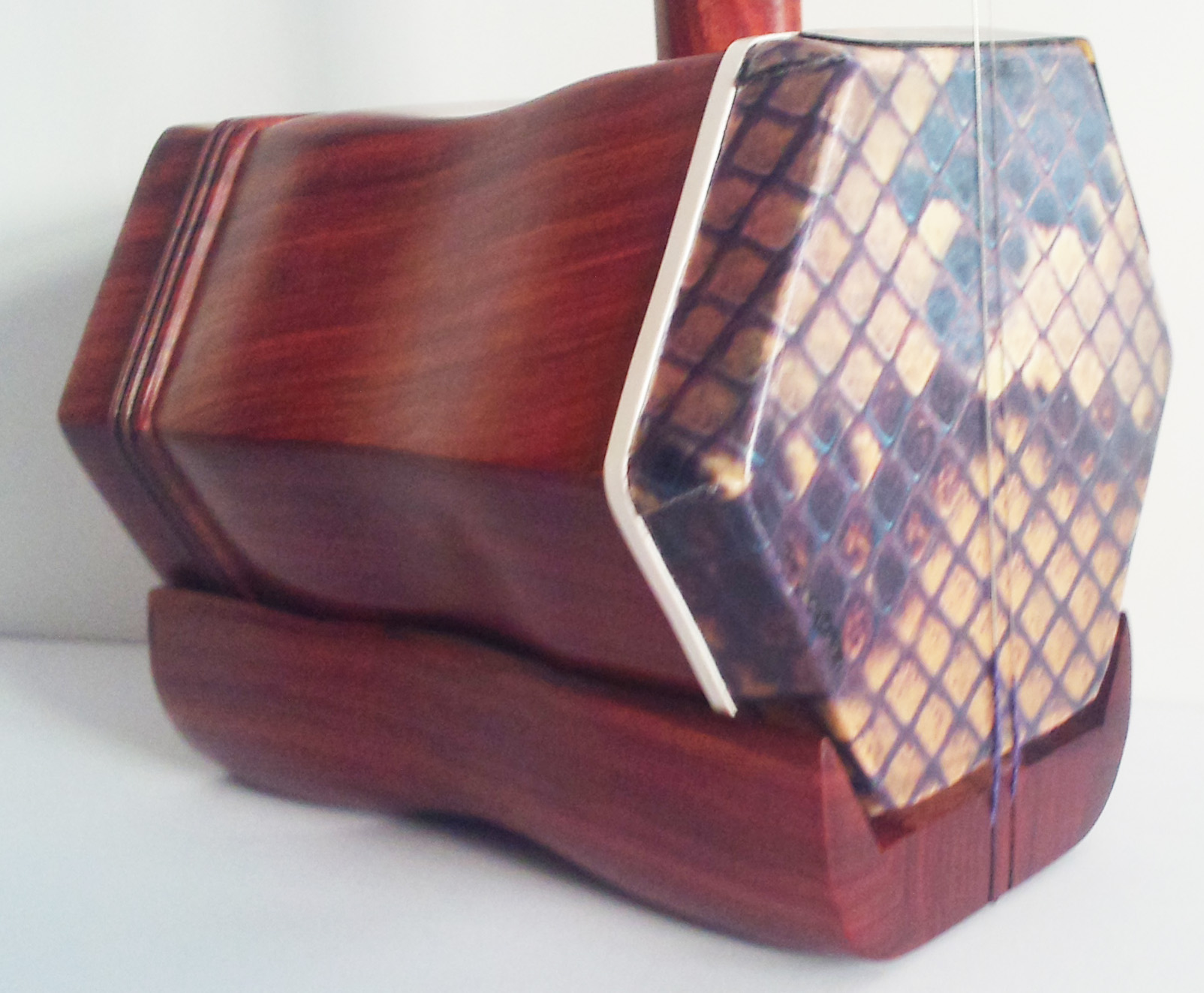

The EcoErhu Membrane The Patented EcoErhu Membrane is the backbone of all our work at EcoErhu. Our vision is to create an acoustically sound alternative for the Erhu performers worldwide. For nearly one millennia, the Erhu, HuQin, or Nanhu has always been made using some form of python or snakeskin. It gives the instrument a unique mellow, human-like tone and in the hands of a virtuoso, it can be one of the most expressive instruments, after the human voice itself. The Erhu relies on the vibratory soundboard: The Skin Membrane, usually made of python skin for its sound production. The main property of the python erhu skin is in its high tensile strength and the ability to withstand pressure at more than 260lb/sq inch. Its strength and elasticity ensures that its vibration causes resonance in the wooden resonator, resulting in the erhu timbre. There are also issues in a modern symphonic Chinese Orchestra with regards to the uniformity in tone and timbre. Even if made by the same luthier, using the same wood, from the same tree, and the thickness of the python is controlled to the highest degree possible, the tones will still be different. In short, no two erhus are identical in tone and where the orchestra needs complete unity and uniformity in tone, this cannot be achieved. One of the important issues is also the control of sale, import an export of python skin products across the world. CITES (Convention of the International Trade in Endangered Species) is strictly enforced in several countries, with the provision for personal instruments in USA, European Union and most of the world. Countries such as Japan and Australia have put an all out ban for the import of such instruments without a valid permit. The CITES Permit, however, is a trading permit, and not a permit that is valid for carrying it on board unless it is within 3 months of approval, and the destination stated on the permit is where one is going. For example, if someone in USA buys an Erhu with a permit from China, the permit, if available, will not enable him to bring it into Japan, even if his name is on the permit, as the permit is not issued in the country of origin where he is travelling. All these issues have caused several major orchestras to replace all the Erhu sections with synthetic skins. The EcoErhu Membrane

The python skin, at the structural level, is not a just

piece of leather, but multiple layers of epidermal, subcutaneous membranes

compressed. As a python is a molting reptile, as the python ages the python

skin increases in thickness by adding on layers and layers of the. The

subcutaneous layers are porous, while the epidermal layers, and the scale

keratin layers are semi-waterproof. This allow for fluid exchanges with the

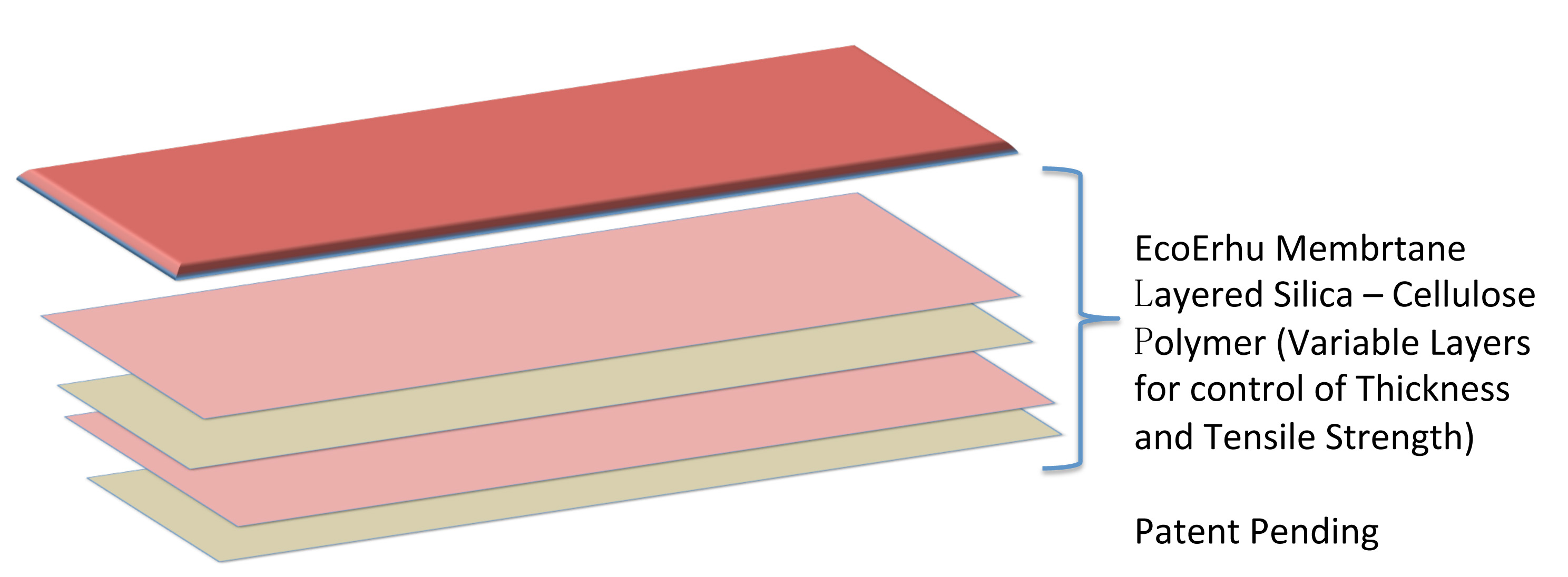

air. In the EcoErhu membrane, we mimic this fully by using a

compressed multiple layer of cellulose-sillica weave, polymer and silica. This

structure allows for the tensile strength to be achieved, at the same time,

restraining it from expansion and contraction when it absorbs or lose moisture.

The multiple layer structure also accounts for the python-skin-like tone, which

even to the discerning virtuoso may not sound any different from the

traditional python skin erhu.  The genuine python skin itself will also have its on

thickness variation, causing its sweet timbre, which is unique to the

instrument. On a general note, the python skin thickness varies in about 0.07mm

thickness per 1meter of the whole skin, getting thicker towards the tail of the

python. There will also be a strip of exceptionally thick subcutaneous layer

running across the length of the entire python, corresponding to the spinal

chord of the python itself. This strip is exactly positioned on the middle of

the python skin and on the erhu, its where the erhu bridge rests across the

membrane. Perfect alignment of these variations is extremely rare in real

python skin, but is fully replicated to the maximum extent and always improved

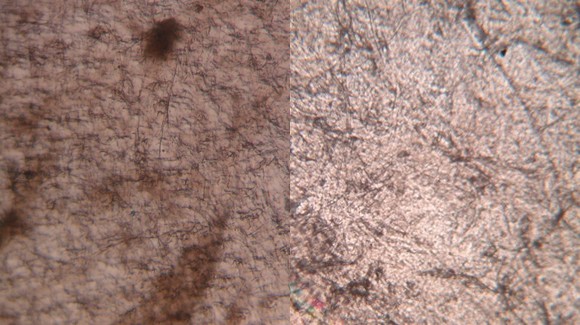

upon in the EcoErhu Collection. On the cellular level, a patented inter-weave of cellulose

and silica fully mimics the structure of the real python skin, giving it the

tensile strength and elasticity. Preliminary tests have made the erhu achieve

more than 260lbs/square inch at 0.38mm average thickness. This is more than

sufficient for the erhu’s maximum performance.  The Python Skin (left) vs The EcoErhu Membrane (magnified 200x)

When you can

determine the thickness, internal slope, elasticity of every piece of membrane,

it becomes a variable one can effectively control in the manufacturing processs

of an erhu. Coupled with techniques of balancing the resonator box

acoustically, EcoErhu have an almost 100 success rate in making the instrument

suit the purpose the musician has in mind. The EcoErhu

Membrane has also been used successfully on shamisen, Jinghu, gaohu and

zhonghu. More details of these instruments will be given at a later stage. A patent is pending

for the EcoErhu Membrane. It’s application details are available upon request

by qualified retailers and organizations. |